Ingenious Solutions from a Transformer Oil Regeneration Plant

How Regenerated Transformer Oil Extends Transformer Life Expectancy

The duty of transformer oil is vital in making certain the dependability and longevity of transformers, offering as both an insulator and coolant. Regrowed transformer oil provides an engaging service to improve these functions by efficiently eliminating dangerous pollutants that jeopardize efficiency.

Relevance of Transformer Oil

Transformer oil plays a vital function in the efficient operation of electric transformers. It mainly functions as a protecting tool, avoiding electrical discharges and making certain that elements run securely under high voltage problems. The oil's dielectric buildings are essential to keeping the integrity of the transformer, as they minimize the threat of failings that can lead to disastrous incidents or pricey downtimes.

Along with its protecting abilities, transformer oil also works as a coolant. As transformers run, they produce heat that should be dissipated to protect against overheating and succeeding damages. The oil distributes within the transformer, taking in and moving warmth away from vital parts, thus maintaining optimal operating temperatures.

In addition, transformer oil acts as a barrier against dampness and impurities, which can compromise the performance and longevity of the transformer. Its chemical buildings assist in reducing the effects of acids and other byproducts that might form in time, adding to the overall health and wellness of the electrical system.

Benefits of Regenerated Oil

Additionally, regenerated transformer oil has a reduced level of impurities, including fragments and impurities that can deteriorate efficiency. This purity not only improves the oil's thermal conductivity yet additionally expands the operational life expectancy of transformers by reducing overheating threats. The boosted thermal security of restored oil ensures constant performance even under high operating temperatures, which is crucial for keeping transformer effectiveness.

Another benefit is its ecological influence. Restored oil promotes sustainability by reducing waste and the requirement for new oil production, thus lowering the carbon footprint associated with transformer maintenance. Reclaimed Transformer Oil. Moreover, the durability of regenerated oil translates to reduced upkeep prices gradually, as less oil changes and less constant equipment downtime are required.

Process of Oil Regrowth

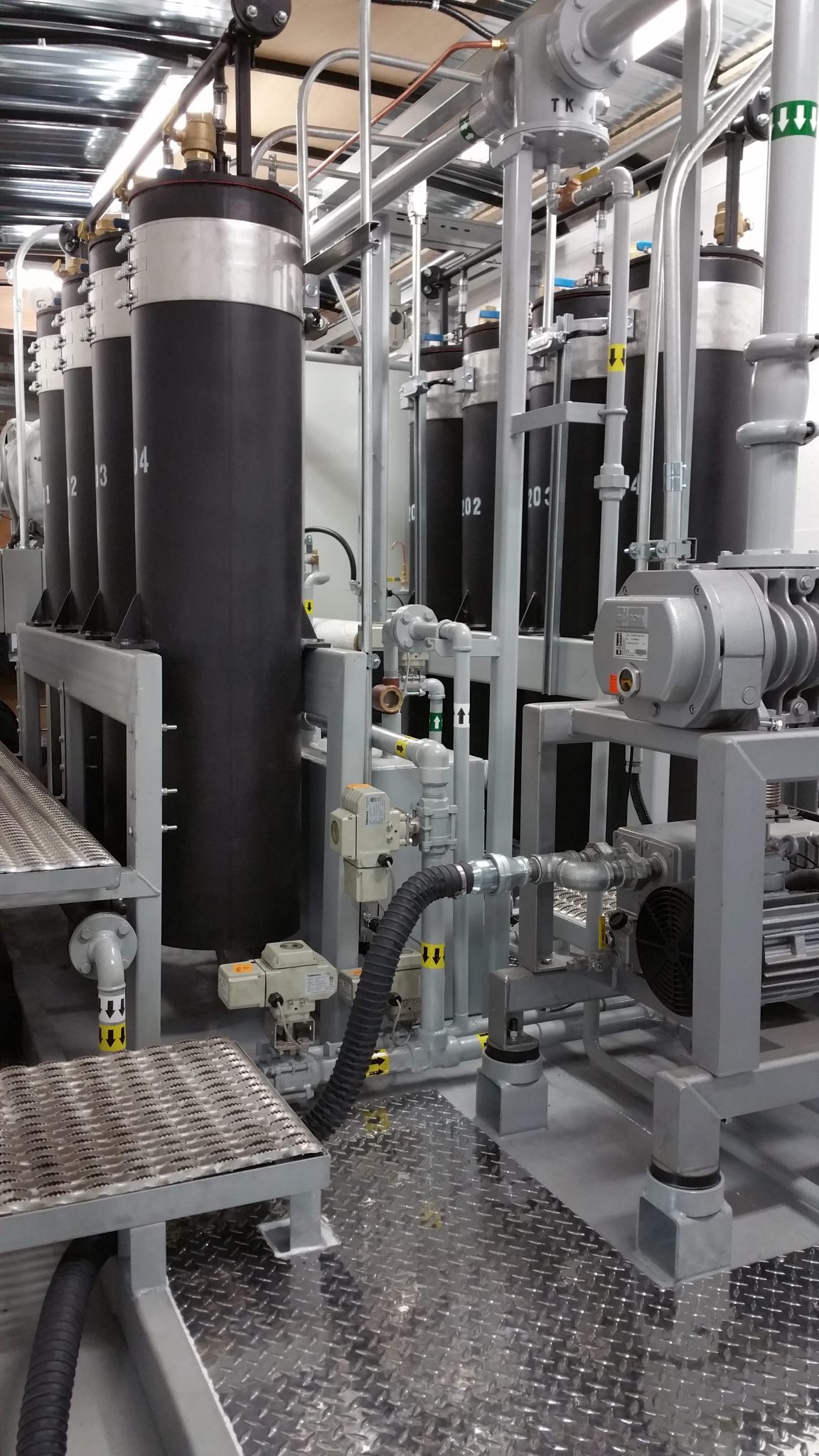

The regeneration of transformer oil involves a methodical process designed to recover the oil's initial residential properties and enhance its efficiency. This procedure normally starts with the removal of the used oil from the transformer, which is after that based on numerous filtration techniques.

The very first step in the regrowth procedure is the purification, where strong contaminants such as sludge, dust, and metal fragments are removed. This is typically adhered to by vacuum distillation, which aids to get rid of moisture and unstable substances, thereby improving the oil's dielectric toughness.

Influence On Transformer Performance

Recovering the homes of regenerated transformer oil considerably influences the overall performance of transformers. Boosted dielectric toughness is among one of the most vital benefits, as it permits for better insulation and minimizes the likelihood of electrical failure. This improvement results in an extra stable operation under high voltage problems, ultimately leading to increased performance.

Furthermore, the elimination of contaminants and destruction items throughout the regeneration procedure minimizes the threat of overheating. Cleanser oil helps with far better heat dissipation, which is essential for preserving ideal operating temperatures. Consequently, the thermal performance of the transformer is improved, permitting higher lots without endangering dependability.

Additionally, the chemical stability of restored oil guarantees long term functional life. It stands up to oxidation and degradation, minimizing the regularity of maintenance treatments and oil substitute. This stability not only adds to boosted performance however additionally straightens with sustainability goals by minimizing waste.

Future of Transformer Upkeep

As improvements in innovation continue to improve the landscape of electric link engineering, the future of transformer upkeep is positioned for considerable transformation. The combination of wise innovations, such as IoT sensors and predictive analytics, enables real-time tracking of transformer health, improving the ability to preemptively deal with problems before they escalate into major failings. This positive strategy not just optimizes functional efficiency but also prolongs the life-span of transformers.

Additionally, the application of expert system (AI) in information evaluation enables even more precise fault discovery and medical diagnosis. By leveraging artificial intelligence algorithms, maintenance teams can identify patterns in operational information that human analysts might forget, resulting in more enlightened decision-making.

In addition, the fostering of environmentally friendly practices, consisting of using regenerated transformer oil, is readied to redefine upkeep methods. This sustainable strategy not just lessens ecological effect yet also enhances the general health of the transformer.

Lastly, the change in the direction of automation in upkeep procedures is anticipated to streamline procedures, reduce downtime, and lower prices. As these advancements proceed to evolve, the future of transformer from this source upkeep will most certainly become much more reliable, reliable, and lasting, making certain the honesty of important electric infrastructure.

Final Thought

The use of regenerated transformer oil substantially improves the operational long life of transformers. By properly restoring dielectric stamina and thermal security, this oil plays an important duty in mitigating threats related to getting too hot and oxidation. The regeneration procedure not only eliminates unsafe pollutants however also minimizes maintenance frequency and oil substitute expenses. Inevitably, the fostering of regenerated oil represents a crucial development in transformer upkeep, making sure ideal efficiency and sustainability in the management of electrical infrastructure.

The duty of transformer oil is critical in ensuring the dependability and longevity of transformers, serving as both an insulator and coolant.Transformer oil plays an important function in the efficient operation of electric transformers. Regrowed oil advertises click reference sustainability by decreasing waste and the demand for new oil production, consequently lowering the carbon footprint connected with transformer maintenance.Bring back the residential properties of regenerated transformer oil significantly influences the overall performance of transformers.The application of regenerated transformer oil substantially enhances the functional longevity of transformers.